Cheese board cleaning washers

CHEESE BOARD CLEANING

Inadequate board hygiene can cause considerable consequential problems for producers. Only on healthy cheese boards that are properly cleaned and cared for can cheeses mature with a well-groomed appearance. This makes it all the more important to clean the cheese boards correctly. For this purpose, we use specially developed brush washing stations in the process to remove stubborn contamination from the surface efficiently and hygienically, as well as downstream thermal disinfection. With this design hygienically perfect results could be achieved.

Cheese board cleaning washers

Combiflex – S

We offer industry-specific solutions tailor-made for our customers. Whether it is a cheese board cleaning system with thermal disinfection, or a special integrated brush washing station for optimum cleaning of even the most stubborn dirt – you can rely on our many years of experience.

Cheeseboard cleaning

Cheese boards

BRUSH WASHING STATION

THERMAL DISINFECTION

OPTIMAL CLEANING

By pressing the start button, the machines are progressively switched on and the selected cleaning and disinfection program is initiated. The cheese boards are then manually removed from the trolleys and loaded onto the appropriately designed 3-track conveyor. The boards are first washed, intensively wet brushed, clear washed and thermally disinfected at 90° Celsius and then rinsed with fresh water and finally blown off with unheated, filtered air. Afterwards, the boards are removed manually and put back into the trolleys.

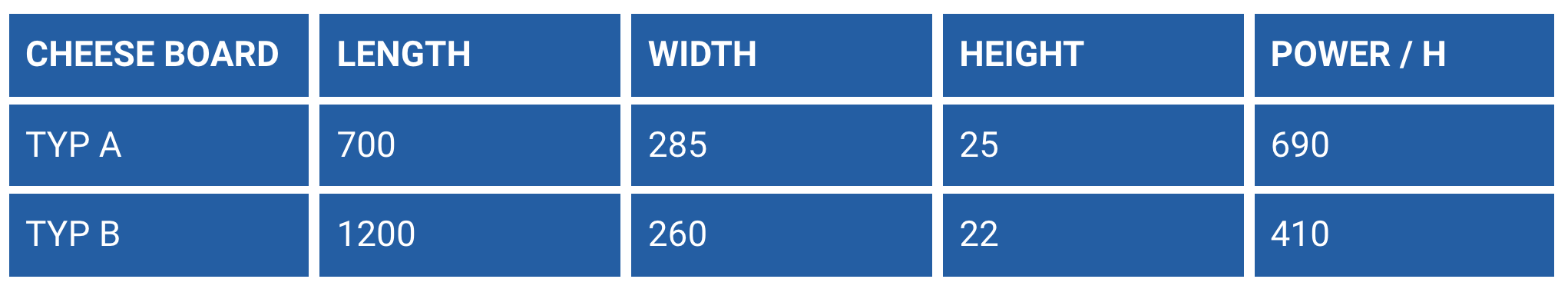

CHEESE BOARD

LENGTH

WIDTH

HEIGHT

POWER / H

Typ A

700

285

25

690

Typ B

1200

260

22

410