Automated cleaning washers

Automation technology and robotics enable the largely autonomous operation of machines and systems. They thus relieve people in modern industrial society of heavy physical, monotonous and unhealthy work. Automation technology also helps to reduce energy costs and increase the efficiency of industrial processes.

Automated cleaning washers

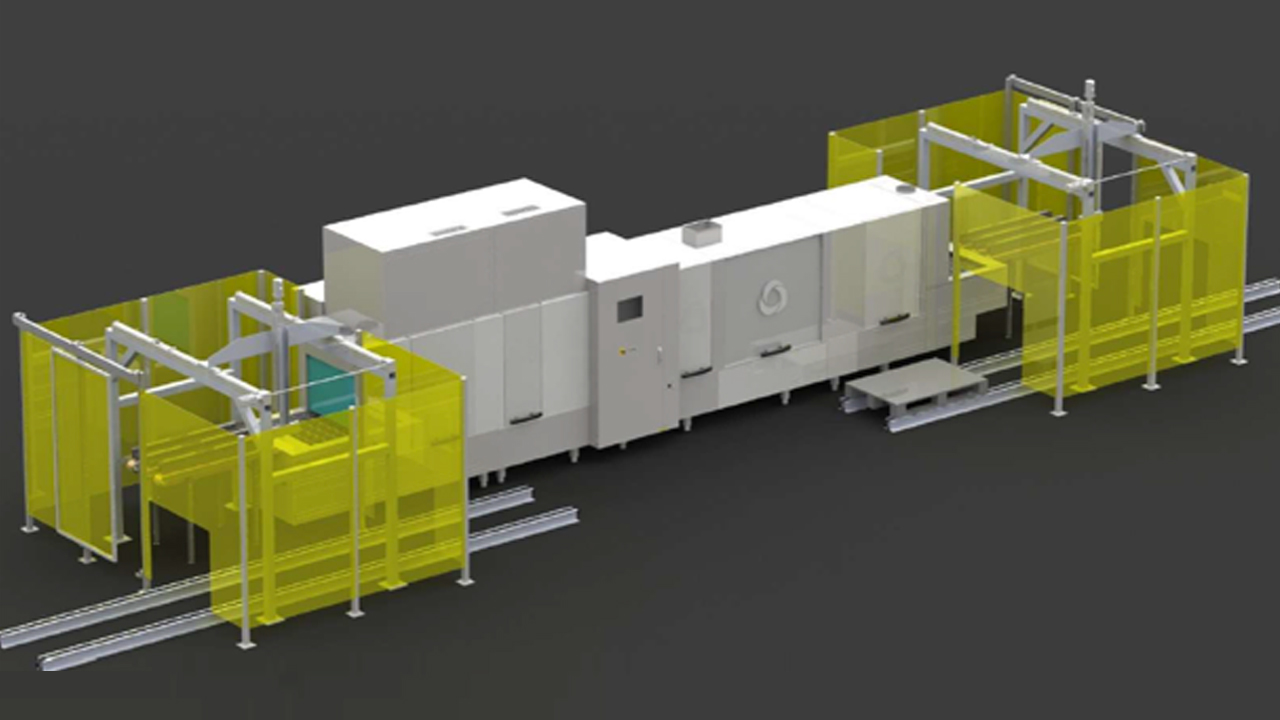

roboflex po 200

HILDEBRAND gantry robot automation for existing as well as new mold cleaning lines

Automatic chocolate mold handling Hildebrand can bring You one step forward. With our ROBOFLEX solution, we can bring all types of chocolate molds into your mold washing line in an automated way. No matter whether it is our best-selling COMBIFLEX washing system, or the system from a market competitor. We have a solution. Whether it is a new plant or an existing old plant, whether it is a 1, 2 or 3 track plant, our ROBOFLEX can be adapted to your needs.

Robot automation for mold cleaning lines

Chocolate molds

Boxes & containers

200 – 400 MOLDS/H

1-3 LANE LINES

FULLY AUTOMATIC

Automated cleaning washers

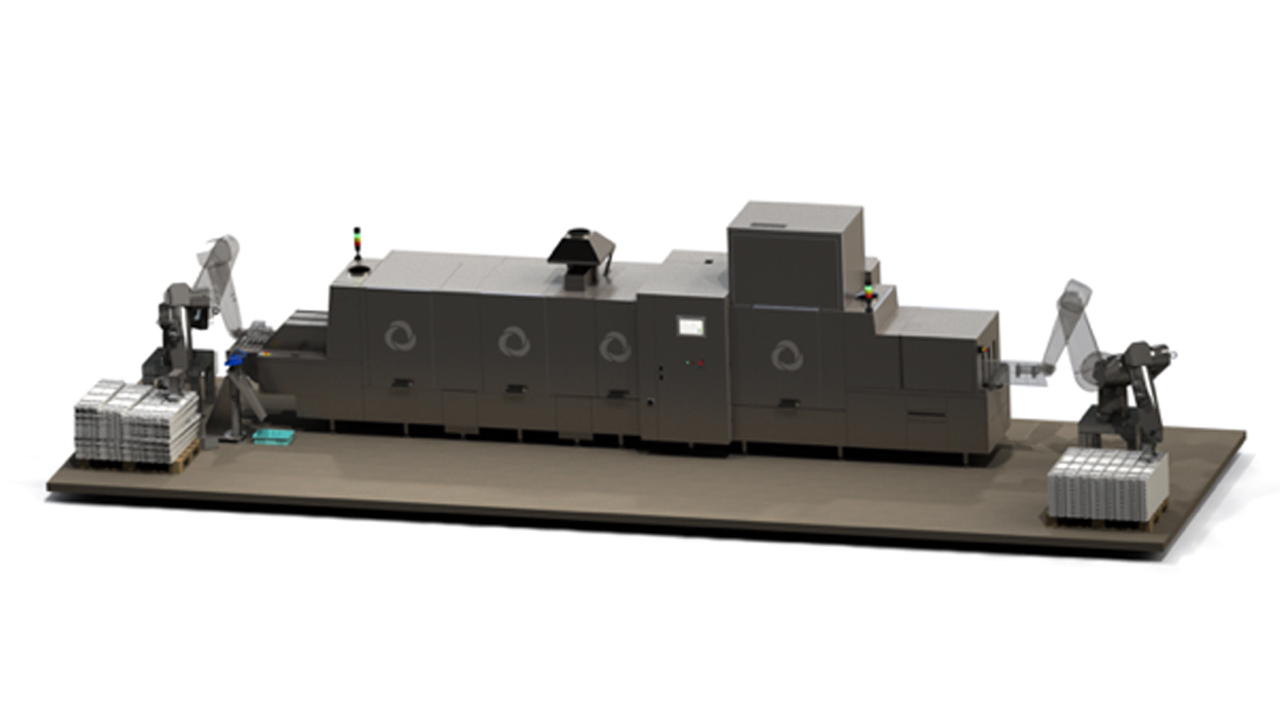

roboflex ro 400

HILDEBRAND 6-axis mold robot automation for existing as well as new mold cleaning lines or format change on chocolate production lines.

The existing mold cleaning line is equipped with a 6-axis mold robot system on the infeed and/or outfeed side. The molds are fed to the loading station on pallets or mold storage carriers. The robot detects stack height and mold type via camera. The top mold is automatically picked up and rotated 90° and placed upright on the belt of the free mold cleaning track. The robot’s working area is monitored electronically and the robot stops as soon as a person enters the danger zone. Thus, no barrier fences are necessary and the area is freely accessible. Depending on the mold size and type, standard gripper systems are available that cover most commercially available mold geometries without the need for retooling.

Robot automation for mold cleaning systems

Chocolate molds

Boxes & containers

6 AXES MOLD ROBOT

LASER/CAMERA MOLD RECOGNITION

FULLY AUTOMATIC

Automated cleaning washers

FULLY AUTOMATED WASHING CENTER

In 2019, we delivered a modern fully automatic washing center to the pharmaceutical industry. Here, pallet medical trays, paloxes are cleaned fully automatically with automatic washing goods input and output control connected to the on-site high-bay storage system.

All process steps are automated and the system offers a maximum of production flexibility as well as economic efficiency regarding performance and energy consumption.

Fully automatic washing center

Pallets

Medical trays

Paloxes

FULLY AUTOMATED

PRODUCTION FLEXIBILITY

LOW ENERGY CONSUMPTION

Your consent is required to display this content from vimeo - Privacy Settings