WE HAVE MORE THAN THREE DECADES OF EXPERIENCE IN CHOCOLATE MOLD CLEANING, BUT THE OPTIMIZATIONS FOR OUR CUSTOMERS ARE FAR FROM FINISHED.

HILDEBRAND PORTAL- ROBOTIC AUTOMATION FOR EXISTING AS WELL AS NEW MOLD CLEANING LINES

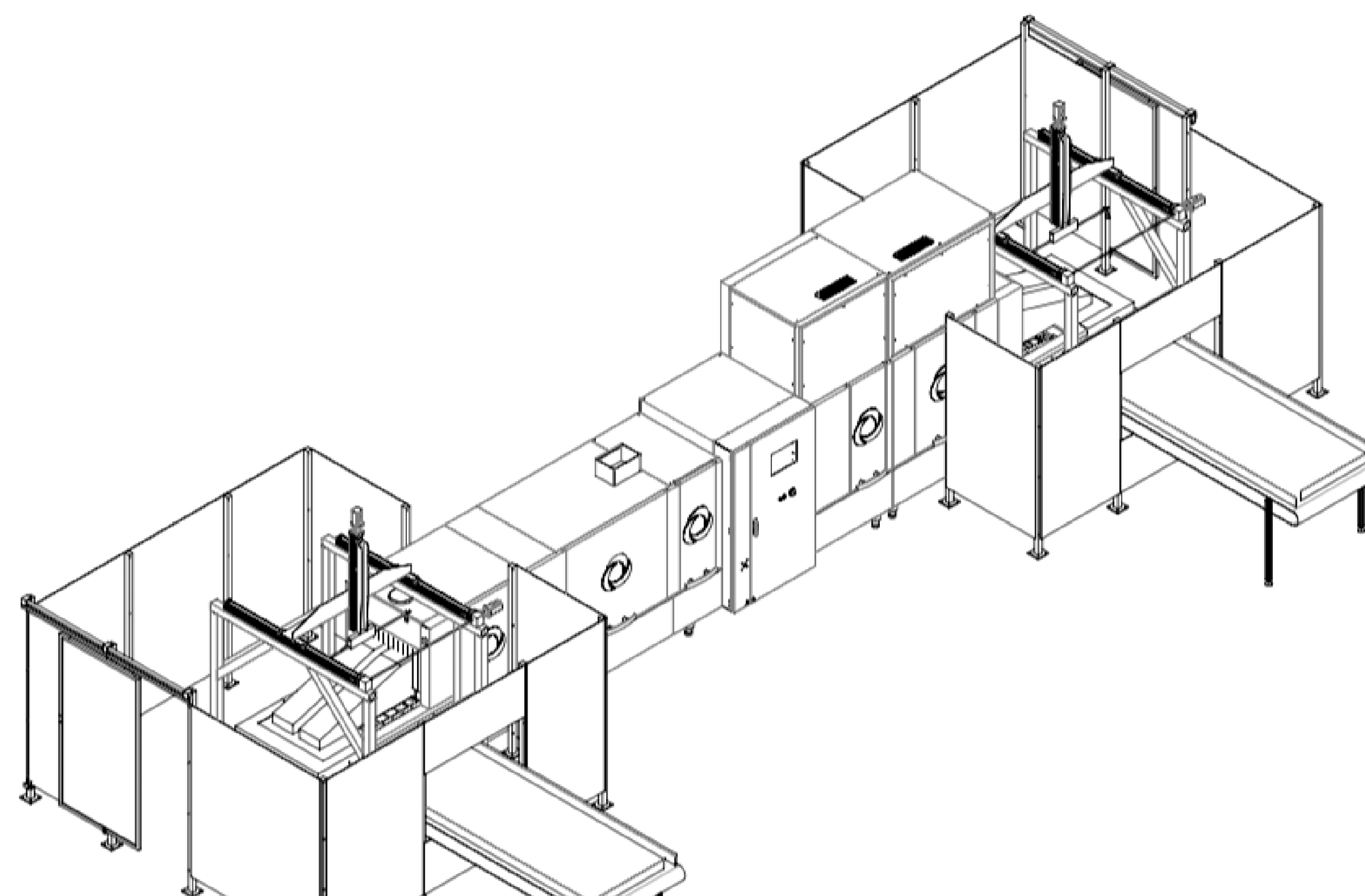

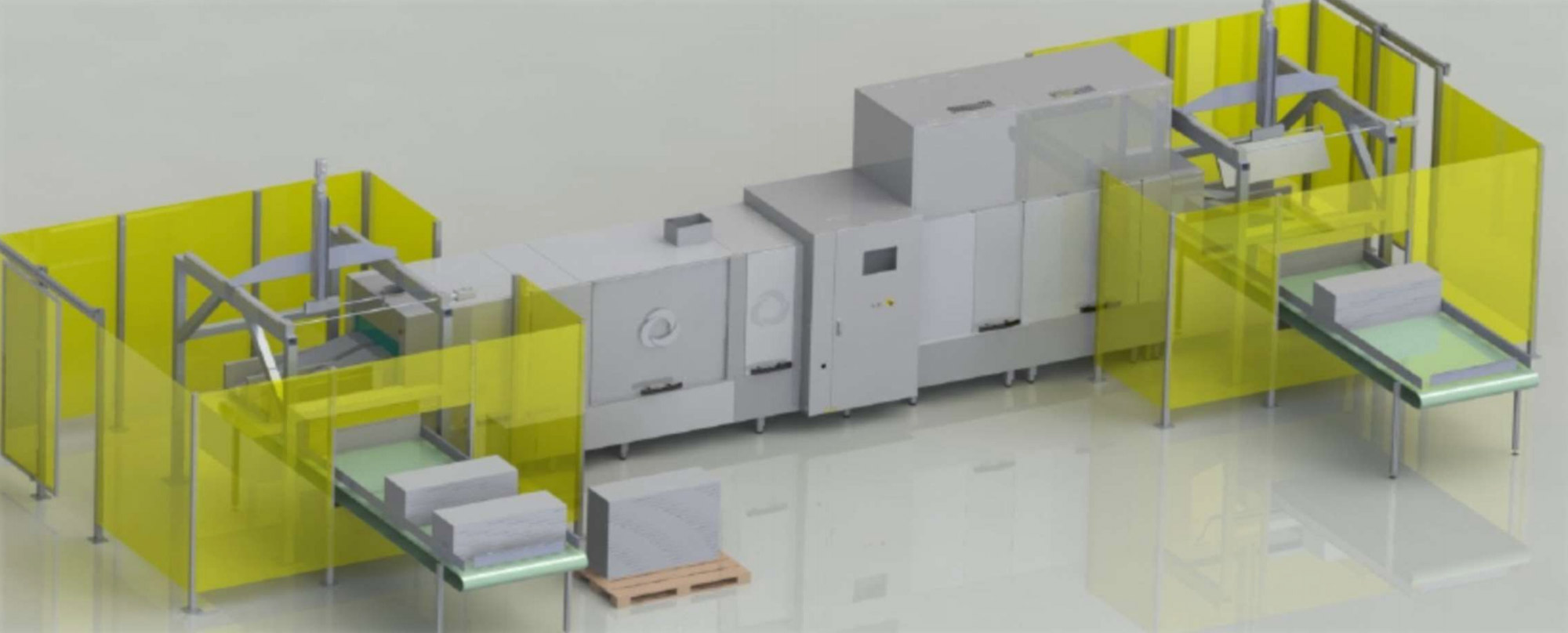

The existing mold cleaning line is equipped with a gantry handling system on the input and/or output side. The gantries have two axes driven by belt drives. The mold is fed via a separate infeed conveyor. The infeed conveyor has space for 6 stacks of 30 molds. This allows autonomous operation for up to 33 minutes. The belt always moves automatically to the loading position, which is located behind a protective grid. The protective grid is only open in the area where the stacks pass through and is appropriately secured and marked. A sensor detects the stack height and the control system then calculates the necessary travel steps. The gantry loader grips the top mold and lifts it. The mold is now rotated by 90 degrees and positioned on the corresponding free track. The gantry then moves onto the stack and picks up the next mold. As soon as the foremost stack is unstacked, the infeed conveyor automatically moves one position further and the process repeats. With this automation, the entire line can be operated by one person, who is only needed for loading and unloading. When the infeed conveyor is full and the outfeed conveyor is empty, the entire line can be operated by one person. This solution saves operators and allows continuous full load operation of the washing line with significant energy cost savings compared to manual operation.

The Offer:

We offer the rotary loader or cross loader. Our sysetm can handle molds up to > 1’200 mm in length, no matter what type of single sheet machine it is.

Our promise:

You too can optimize your production process in cleaning of chocolate molds. By using the ROBOFLEX system, the loading and unloading of the cleaning process can be automated. This will save you considerable personnel costs. Another advantage, which is definitely worth mentioning, results from the fact that the washing system is always operated at full load and there are no interruptions during loading. This saves you significant operating costs such as electricity, water and washing chemicals. Quite simply, we grab the molds and bring them vertically into the magazine of your cleaning machine.

THE ROBOFLEX 200 LINEAR PORTAL 2 AXIS MOLD ROBOT

For customer-specific requirements, for example for mono lines with feeding from the mold stack, we offer an economical 2/3 axis linear gantry robot solution for loading and unloading the molds from the mold cleaning system.

FEEDING FROM MOLD STACK

MOLD CLEANING SYSTEM

OUTFEED MOLD STACK